For the 2017/18 formula hybrid season, I wanted to shift my focus away from mechanical work and into the electrical systems of the vehicle. I ended up taking on a complete revamp of the low voltage system, which primarily functions as a safety circuit for shutting down systems in the event of failures or shorts. Our previous system was made on a breadboard, and was poorly documented and relatively physically unstable.

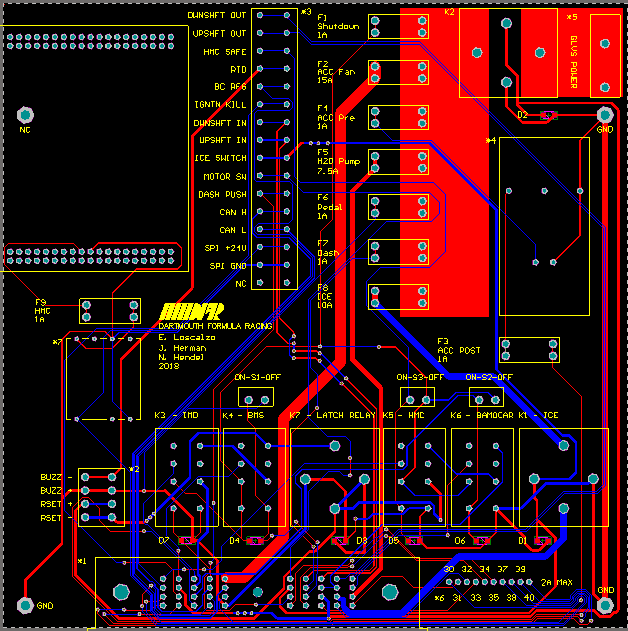

To start, I spent time studying the rules and the previous schematics, and then re-built a wiring diagram for the full system. Then, I used Altium to design a 2 layer PCB. All the parts were sourced on digikey and modeled in 3D. Once confident, I ordered the PCB and soldered on the surface components. I repurposed a mechanical box from prior project cycles, and housed the PCB as well as some buttons for operation. The system worked amazingly well and was fully waterproof.

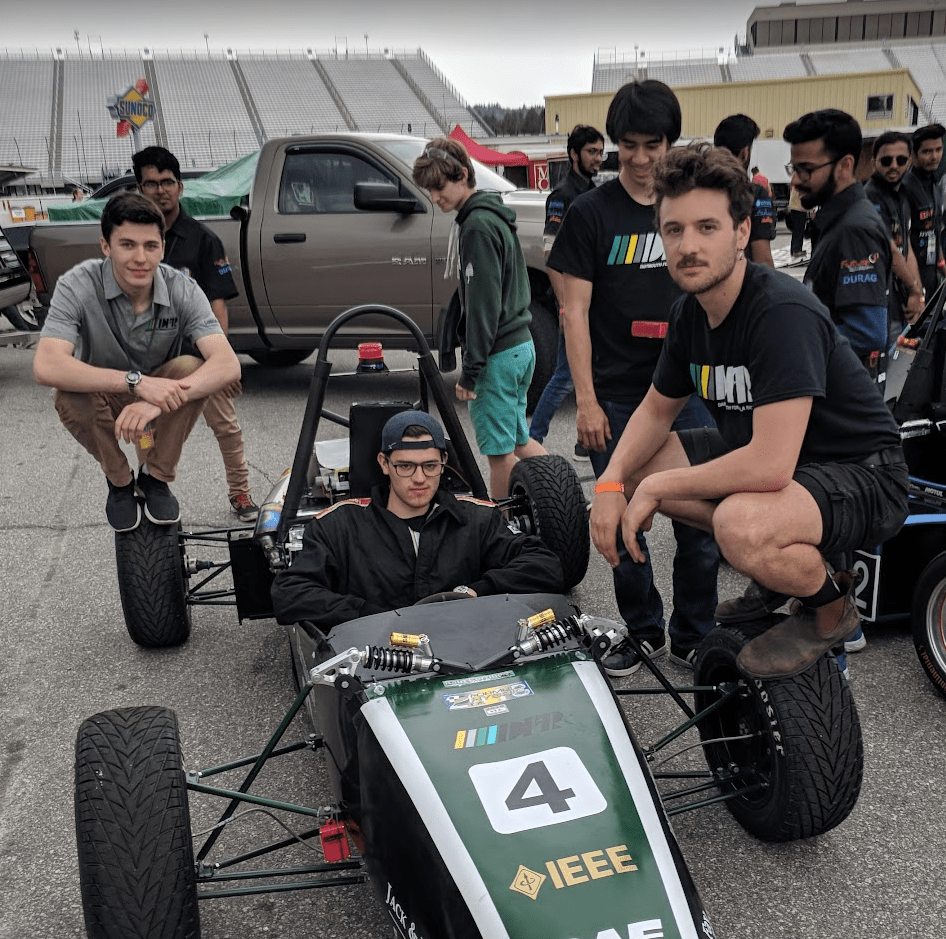

We had a really great year at competition, taking home 1st place in our hybrid category. A big improvement from 2016!

As a bonus, I also got to weld up a new gas tank. This was fun because I didn’t have much experience welding aluminium prior to this. The gas tank had to be a very funky shape to fit in the car and a specific capacity to meet regulations.