During my summers in 2016 and 2017 I worked for a small horticultural lighting startup called HortLED in Ithaca, NY.

My main design project was a 1 kW Chip on Board (COB) style LED fixture. Responsibilities included part selection, 3D design, BOM management, fabrication, assembly, wiring, testing.

Additional projects included development and fabrication of a CNC 2 axis light characterization machine, LED power systems for the MIT OpenAg project, and designing various prototype hydroponic concept systems.

My time at HortLED was awesome. Being such a small shop, I was able to work directly with the lead engineer and got hands on experience with all stages of the product development life cycle.

Thanks so much to my mentor Alex for providing this opportunity for me.

HPS Killer

This 1 kW lighting fixture used 6 COB broad spectrum (white) LEDs and was designed to replace the industry standard high pressure sodium bulbs that are commonly used in greenhouses. The LED’s are attached directly to a large aluminum heat sink. Fans are used to direct air across the fins. Light drivers are mounted onboard. Framing made of acrylic is used to house all the components and offer mounting features for hanging the fixture.

Shown below are some “finished prototype” close ups, how the light looked turned on, and a shot from a field test day at Ithaca College.

Light Characterization System

This system was fully designed and built in house in order to automate a previously manual process of characterizing light output. The system consists of a welded together frame from square tube steel, a 2 axis linear actuation system made from aluminum rail, and a tool holder that accepts our light measuring device. The linear rail system was controlled by a raspberry pi, through which we sent commands to move the tool in a 4’x4′ grid at increments of our choosing. At each location, the tool would stop and record a measurement. The light fixture could be set at multiple heights as well in order to understand the light output spread in 3 dimensions.

To characterize light at HortLED, we used a Photosynthetically Active Radiation (PAR) meter to measure the amount of photons (or expressed as energy in Watts) over an area, at various distances and relative locations to a light source.

Below you can see two different light sources being measured.

Concept Hydroponics

As part of my time at HortLED, I dreamed up a couple small hydroponic systems. The laser cutter and pneumatic nail gun came in handy to make these quick and light prototypes. I experimented with “snap together” style design to make these very fast to assemble.

The vision for these systems was to provide desktop or in-store scale systems for growing fresh vegetables.

Power Systems

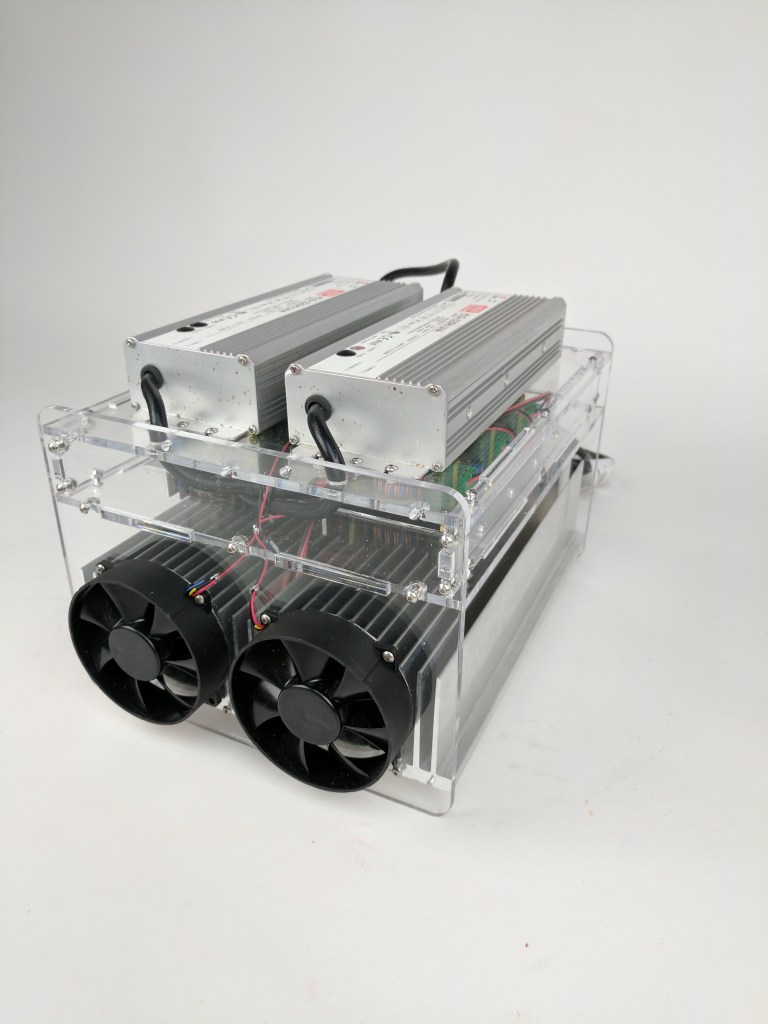

These power distribution systems were designed for a project in collaboration with MIT Media lab OpenAG. This system takes in building AC and converts it to DC needed to drive LED lights. Additionally, enough terminal points are provided so that many lights can be directly connected and driven simultaneously.

What is this for?

LikeLike